A significant aspect of pipework maintenance repair is how to repair leaking defects. Composite repairs cannot be used to live leak seal as the leaking fluid will contaminate the outer surface of the pipework preventing the composite repair from adhering to it.

Therefore to enable composite repairs to be used on leaking defects, first the leaks must be mechanically sealed. Walker Technical has developed a range of simple mechanical leak sealing solutions for processes operating under the following conditions.

Class 1 and 2 repairs according to ISO 24187 cover design pressures up to 20 bar and design temperatures up to 40°C the majority of the utility service systems. This class is intended for those systems that do not relate directly to personnel safety or safety-critical systems.

Repair Class

Class 1 & 2

Typical Service

Drains, cooling media, sea water, fire water,

potable water

Design Pressure

<20 bar

Design Temperature

<40°C

Benefits

The intention of the leak sealing capability offered by Walker Technical is to provide a temporary (mechanically) leak sealing solution, prior to the application of a compliant Technowrap composite repair providing the client with a long term solution up to 20 years.

More Features

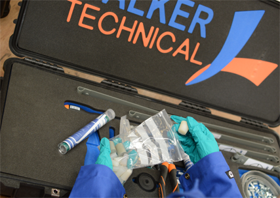

PACKAGED

Packaged in a

protective case for

convenient transport

RANGE OF SOLUTIONS

Sealants available for

majority of

applications

STANDARDS

Meets all Process

Safety Management

requirements

Our certified technicians have years of field experience. They are well-trained and well-equipped with the appropriate equipment to handle leaks.

Leak Sealing – In Action

Leak Sealing – In Action

A recent scope of work involved a 48” caisson with 40+ through wall defects over a vertical length of 23metres. A long term repair solution with live leak sealing was required to reinstate the integrity of the caisson – a crucial component to platform operations.