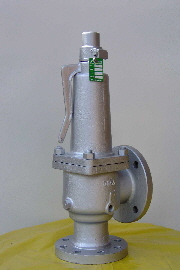

Safety Valve Overhauls

Safety is the top priority in every process industry. Which is why critical components such as safety, relief and emergency shutdown valves are given special treatment by Comid.

Safety is the top priority in every process industry. Which is why critical components such as safety, relief and emergency shutdown valves are given special treatment by Comid.

All safety valves are tested and certified upon completion of the overhaul and our operating systems have been externally verified (See Accreditations).

Comid also has the capacity to carry out in situ testing of safety valves through √eri-Test, Go to the √eri-Test page to get more information on Comid’s system for testing safety valves in situ.

Control Valve Overhauls

Some of the most demanding sectors of British Industry – from oil, gas and chemicals to power generation, food processing, brewing and paper making – depend on control valves for effective performance. The Comid valve repair and reconditioning service helps to keep these critical components operating at peak efficiency

Valve Repair

Valve Repair

Comid has a wealth of experience as well as the capacity to repair all sizes of safety, relief, gate, globe, check, ball, plug etc. valves.

Our workshop is well equipped and we have specialised lapping facilities for all types of valve seats.

Our engineers are of the highest quality to ensure that we continue to meet our customers’ requirements as well as their changing needs.

Valve Supply

Valve Supply

Comid hold large stocks of Gate, Globe, Check, Parallel Slide, Ball and Plug Valves ready for immediate despatch. Materials: WCB, A105, LCC, CF8M, C. IRON, D. IRON and some exotics i.e. ALLOY 20 & MONEL.

Valves from 1/2″ to 24″ NB, FLANGED ANSI, BS10, BS4504, Screwed, Socket and Butt Weld ends.

Valves not in stock can be sourced from our extensive range of suppliers to give you the best possible price and earliest delivery.

Reconditioning

Comid provides a complete – and guaranteed – service in valve repair and reconditioning, using skills and experience developed over many years and in every sector of industry.

Valves are reconditioned to the highest standard and are tested to the relevant standards to ensure that they are as effective and efficient as they were when new.

On – Site Facilities

On – Site Facilities

Comid Engineering Ltd offers a comprehensive package of on-site services to ensure efficient, reliable plant operations. This service embraces emergency repair, maintenance and repair contracts and the installation of new plant and equipment. With a bias towards Valve, Pipeline and Boiler maintenance which forms the core of Comid’s business.

A comprehensively equipped 20ft long steel bodied container customised as a transportable workshop is offered to support the service.

Workshops house machinery for turning, drilling, welding and hosts an extensive range of hand tools and lifting equipment together with special purpose valve lapping and testing equipment. Lapping machines are carried for in-line valve re-seating. These machines are fully portable, driven by pneumatic motors and are designed for in-situ repairs to Gate, Parallel Slide and Safety valves, of paramount importance when valves are welded in line or impractical to remove for service.

Safety valve testing, overhaul and certification can be carried out within the confides of the mobile facility reducing downtime and in some cases eliminate the need to send valves off site to the service centre.

Comid provide skilled competent labour to carry out all disciplines outlined above. All site engineers carry a CCNSG passport and are trained in all aspects of health and safety.